Products Information

- Machinery Equipment TOP

- Products Information

- Romag Filteration Screen (Treating Overflow Water of Heavy Rain)

Romag Filteration Screen (Treating Overflow Water of Heavy Rain)

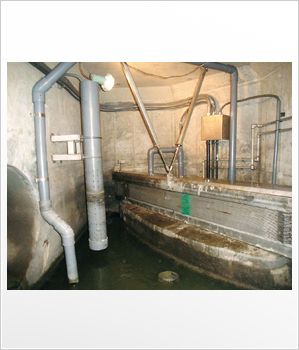

This filter screen developed by the Swiss company Romag is intended to prevent combined sewer overflows (CSOs) in a combined sewer system.

If, in rainy weather, the amount of storm water flowing into the sewer line of a combined sewer system exceeds the sewer line's water collection and handling capacity, both storm water and sewage will flow over the overflow weir of the storm overflow chamber installed in the sewer line and be discharged directly into the public water area. However, garbage, deposits, plastics, waste paper, or other detritus accumulating in the sewer line will also be discharged, contaminating the public water area.

Japan requires the production of pollutant loads to be discharged with overflows, such as garbage.

Romag Filteration Screen (Treating Overflow Water of Heavy Rain) catches garbage and other detritus simply by having the screen facility installed on the overflow weir of the storm overflow chamber, and it can prevent environmental pollution at low cost. This screen can also be installed in an existing storm overflow chamber without carrying out large-scale modifications, prevent pollution of the public water area by impurities to be discharged with overflows, and, as a result, conserve the environment of the public water area.

Application

- Storm overflow chamber of existing combined sewage system

- Inlet of storm water retention facilities, etc. and water intake of power generation and water intake facilities

- Other

Features

Romag Filteration Screen (Treating Overflow Water of Heavy Rain) catches impurities contained in sewage on the flat plates placed at equal intervals (scale spacing: 4 mm) and scrapes off the caught impurities with the scraping blade reciprocating on the screen. Then, the impurities flow down into the intercepting pipe and are sent to the sewage treatment plant.

This screen consists of a screen body, a scraper, a control panel, a hydraulic unit, and water level gauge. The screen is installed on the overflow weir of the storm overflow chamber, where it constantly detects the water level of the sewer line through the water level gauge installed in the storm overflow chamber. The scraper will automatically start to operate if the water level rises to the shuttering board of the screen. It will automatically stop operation if the water level drops below the shuttering board.

Since a module unit system is used, an appropriate model can be selected for the place of installation, and the screen can be easily installed.

To minimize maintenance costs, a material highly resistant to corrosion (SUS316) is used for the screen, and the screen has a simple but robust structure.

In public water areas, where measures to protect appearance and landscape are prioritized, this screen is effective as a simple, quickly functional solution to improve combined systems.

- This screen can be installed in existing storm overflow chambers without large-scale modifications.

- The amount of pollution loads by impurities flowing out in rainy weather can be reduced at low cost.

- A single screen can cover the overall length of a weir from 1 m to 10 m.

- It is not necessary to store or carry out caught impurities.