Products Information

- Machinery Equipment TOP

- Products Information

- SPIRAC Shaftless Conveyor

SPIRAC Shaftless Conveyor

The shaft-less conveyor is thoroughly hermetic and capable of conveying substances in the horizontal, vertical, and oblique directions.

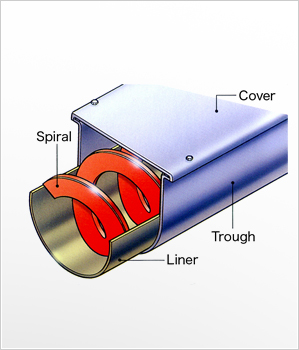

SPIRAC Shaftless Conveyor, which rotates the hollow steel spiral conveyor inside SUS casing, conveys substances without causing adhesion, entanglement, or bridging.

Since the spiral conveyor is supported only by the drive-side bearing, casings can be connected by means of a flange-like piping, and it is easy to convey substances in the horizontal, vertical, and oblique directions and change the course of conveyance. You will no longer need to prepare installation space for conveyance systems or install unnecessary peripheral appliances for them.

Application

- Sewage treatment

- Night soil treatment

- Other

Features

-

Substances can be conveyed in the horizontal, vertical, and oblique directions.

Since the spiral conveyor is supported by the bearing on one side, casings can be connected to each other by means of a flange.

(The conveyor has no shaft, and its conveyance capacity rate can be increased by the space originally required for the shaft.) -

The structure is less likely to cause adhesion, entanglement, and bridging.

The spiral conveyor is free of the problems of adhesion, entanglement, and bridging of conveyed substances because it has no rotary shaft.

(A conveyor with a shaft will face problems with clogging of the intermediate bearing with screening residues.) -

The hermetic structure can prevent the spattering of conveyed substances and odors.

The hermetic structure can prevent the spattering of conveyed substances and the spread of odors.

-

A conveyor can convey substances for 10 meters in the longitudinal direction and 30 meters in the transverse direction.

The strong but flexible hollow steel spiral conveyor has realized long-distance conveyance.

-

It is ideal for a delivering conveyor.

The hollow spiral conveyor is less likely to cause adhesion, entanglement, and bridging of conveyed substances and can also demonstrate outstanding performance as a delivering conveyor to be installed, for example, in the lower area of a hopper.

- A polyethylene liner is inserted between the conveyor and the trough and provided with a wear indicator, which will change the color of the liner from red to yellow if it is worn 9 mm or over. This makes it easy to determine when the liner must be replaced.

Dehydrated cake, screen residues, and grit generated by sewage treatment facilities can be conveyed in any of the horizontal, vertical, and oblique directions as you desire.

-

Transverse-axis conveyor

A conveyor can convey substances as far as 30 meters in the horizontal and oblique directions.

Eight models with conveyance capacities from 2 to 60 m³/h are available. -

Vertical-axis conveyor

A conveyor can convey substances 10 meters in the vertical direction.

Five models with conveyance capacities from 2 to 20 m³/h are available.